— 100 Year Window Resources —

PRODUCT INFORMATION

Standard Product Information: Any deviation from this is possible, but these are Hull Millwork’s standards for the 100 Year Window

- Wood Species: Sapele

- Hardware: Cast Brass lifts, latches, and pulleys from SRS Hardware

- Weight System: Steel bar weights with cotton sash cord

- Putty Glazing: Sarco Dual Glaze with acrylic latex or silicone 1 bedding (depending on finish)

- Glass: 1/8” double strength glass or Pilkington’s Spacia Vacuum Insulated Glass

Testing Results

| Test Type | Test Method | Measured | Allowed |

| Operating Force | A440-17 LS-Breakaway | 160.1N (36.0 lbs.) | 230N (51.71 lbs.) |

| Open | 29.35N (6.6 lbs) | 180N (40.47 lbs.) | |

| Close | 30.2N (6.8 lbs.) | 180N (40.47 lbs.) | |

| A440-17 US-Breakaway | 169.1N (38.0 lbs.) | 230N (51.71 lbs.) | |

| Open | 32.03N (7.2 lbs) | 180N (40.47 lbs.) | |

| Close | 0.7N (6.9 lbs.) | 180N (40.47 lbs.) | |

| Force to Latch | 8.9N (2.8 lbs.) | 100N (22.48 lbs.) | |

| Air Infiltration | ASTM E 283 | 300 Pa (6.24Psf) 1.10 L/s m2 | 1.5 L/s*m2 |

| (0.22 cfm/ft2) | (0.30 cfm/ft2) | ||

| Air Exfiltration | ASTM E 283 | 300 Pa (6.24Psf) 1.25 L/s m2 | 1.5 L/s*m2 |

| (0.25 cfm/ft2) | (0.30 cfm/ft2) | ||

| Water Resistance | ASTM E 547-220 Pa(4.59 Psf) | No Leakage | No Leakage |

| Deflections | ASTM E 330-Span | No Damage | No Damage |

| Positive 1440 Pa (30.08 Psf) at meeting stile | 9.70mm (0.382’) | Reported | |

| Negative 1440 Pa (30.08 Psf) at meeting stile | 10.69mm (0.421’ | Reported | |

| Structural | ASTM E 330 Span L/500 | No Damage | No Damage |

| Positive 2160 Pa (45.11 Psf) | 0.25 mm <0.01” | 2.74 mm (.108”) | |

| Negative 2160 Pa(45.11 Psf) | 0.25 mm <0.01” | 2.74 mm (.108”) | |

| Forced Entry | ASTM F 842 Grade 10 | No Entry | No Entry |

| Deglazing | STM E 987 | ||

| Vertical Stiles at 320 N (71.94 lbs.) | Passed | <95% | |

| Horizontal Stiles at 230 N (51.71 lbs.) | Passed | <95% |

THERM Testing Results

| Test Type | U-Factor | R-Value |

| Single Pane Glass | 0.709 | 1.411 |

| Single Pane Glass with a Storm Window | 0.517 | 1.935 |

| Spacia Vacuum Insulated Glass | 0.269 | 3.72 |

Click here to download Product Information

HOW TO MEASURE

New Construction Windows Measuring Steps:

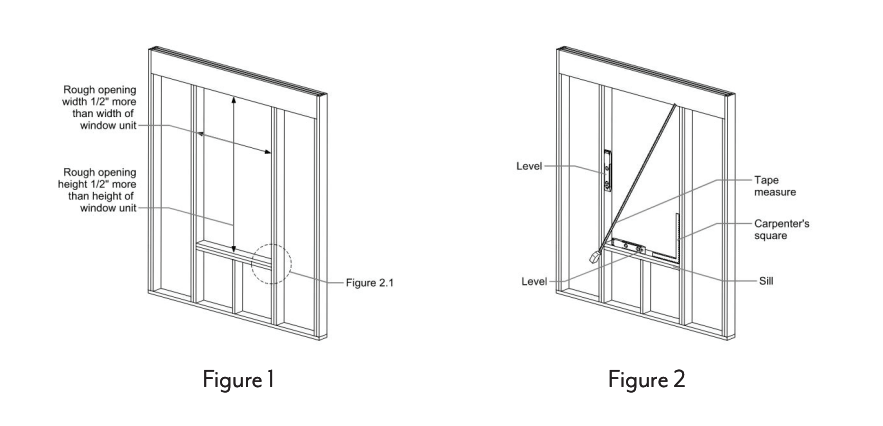

- When measuring or talking about window sizes, it’s always width first then height. (See Figure 1)

- You will need to measure three different places where the window is installed, which is called the rough opening.

- First, find the opening’s width by measuring in three places. One at the top, one at the center, and one at the bottom measuring from face of stud to face of stud. Circle the smallest measurement. This is your width size.

- Next, find the opening’s height. Again, you’ll need three measurements. One on the far left, one on the center and one on the far right. Circle the smallest measurement. This is your height size. (See Figure 2)

- The last measurement you’ll need is the depth.

Replacement Windows:

Please note the following:

- The existing frame jamb depth (“pocket”) must be 3 1/4” or greater.

- If the existing windowsill is not square, level, and plumb, installation may be complicated and additional trim work may be needed. Consider professional installation assistance.

- Record each window’s location in the house in a manner that clearly identifies it.

- If there is more than 1/8” deviation within each set of measurements, investigate the cause and seek professional assistance to correct problems.

- Perform all measurements on each window before going to the next window.

- Individually measure each existing window to be replaced. Do not assume similar looking windows are the same size.

- Measure accurately, to the nearest 1/8”.

- If a group of windows on one wall are all very similar in height, consider using the smallest height measurement for all windows in the group. This will maintain a pleasing appearance. This choice however could result in additional trim work on installation.

- Measuring an existing sloped-sill picture or transom window for replacement is more difficult but the goal is the same. Measure the width between the side jambs, not including any stops/trim (wood-to-wood). Measure the height from the true sill to the head of the window. Partial disassembly of the existing window may be necessary. Due to the difficulty in measuring correctly, professional assistance is recommended.

Replacement Windows Measuring Steps:

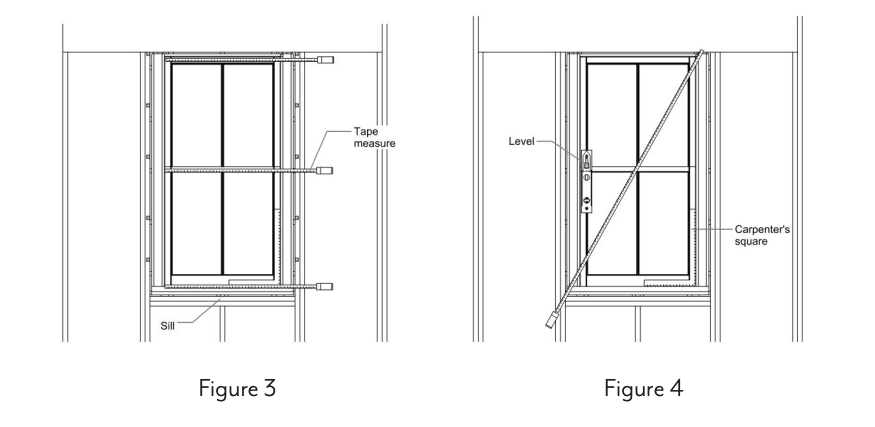

- Measure the width. Measure the width between the side jambs (wood surface to wood surface) in three places: top, middle, and bottom. Temporarily remove jamb liners if necessary and avoid any stops, weatherstrip, balance cords, pulleys, etc. Record your measurements. (See Figure 3)

- Measure the height. Measure the height from the head to the sill in three places: left side, middle, and right side. At the head, measure directly from the wood header avoiding any stops, weatherstrip and liners. At the sill, measure on the exterior side directly behind the sill stop at the highest point of the sloped sill. Record your measurements.

- Check your sill angle. If installing your replacement window into a wood double-hung with a sloped sill, determine and record the slope angle on a worksheet.

- Confirm squareness of existing window. Confirm the existing window is square by measuring both diagonals. If the two diagonal measurements differ by more than ¼”, an out-of-square adjustment in the width of the window must be made. The adjustment is determined by creating a plumb line (using a level) from each corner to the sill or head. Using a plumb line that falls within the window opening, measure the out of square adjustment. Subtract this measurement from the smallest width measurement. Record this adjustment width as the smallest width. (See Figure 4)

Click here to download How to Measure

ORDER PROCESS

- Fill Out 100 Year Window Project Form

- Name

- Phone Number

- Relationship to project (Homeowner, designer, architect, builder/contractor, other)

- Job location

- Budget

- Anticipated Start Date

- Anticipated Completion Date

- Project type (Commercial, residential)

- Job type (New Construction, replacing replacement windows, replacing historic windows)

- A Hull employee will reach out if they have any other questions about the information provided. This information will be used to generate a proposal. Acceptance of this proposal will result in an invoice for 50% deposit but depends on size and nature of project.

- Shop drawings will be generated after deposit has been received. A quote includes the initial draft of shop drawings plus one (1) revision submittal. Additional revision submittals will be billed at a rate of $100.00 per hour.

- Upon our receipt of your shop drawing approval, Hull will schedule production and submit to you an estimated completion date. Large projects will require an additional progress payment midway between the production sequence and the scheduled delivery. The final balance will be due upon completion.

Click here to download the Order Process

MAINTENANCE AND CARE

At Hull Millwork, we pride ourselves on producing the highest-quality products made from solid wood. Each 100-Year Window is made with sapele or Forest Stewardship Council–certified hardwood and is guaranteed against warping and manufacturing defects.

Hull is committed to ensuring our customers have the best possible experience with our products. With proper maintenance and care, the 100-Year Window can last a lifetime. Although Hull stands behind this window for 100 years, no window can withstand the elements without proper care and upkeep. Failure to follow the Maintenance and Care guidelines will void the Hull 100-Year Window Warranty. See the Hull 100-Year Window Limited Warranty section for more details.

Maintenance and Care Checklist

- If windows are delivered primed only, final finish must be applied within 14 days of delivery to ensure quality and to comply with the Hull warranty. A good coat of paint will preserve the quality of the wood trim.

- Operate sashes frequently as weather conditions change across seasons.

- If the sash stop is adjustable, adjust it accordingly for proper operation in varying seasonal weather conditions.

- Ensure the sash track is free of dust and debris before waxing it.

- Remove mud dauber nests from the check rails in the winter.

- Check glazing putty for any cracking or releasing from the glass. This is rare, but if it does happen, contact Hull at [email protected] before making any repairs.

- Ensure the caulking and perimeter sealant joints are stable, without holes or releasing from adjacent substrates.

- Inspect the windows twice a year for signs of paint wear or wood damage. To keep your windows in good working order, treat them with wood paste wax along the sash channels. Hull uses and recommends Trewax Paste Wax.

- Inspect the glazing putty for signs of cracking or leakage. Failure to properly maintain the windows will void the warranty.

- Inspect frames twice a year for signs of deterioration. The sills are especially vulnerable to wear and paint fade. Repaint windows every 3–5 years. Ensure caulking is not excessive and does not cause water dams or hold water against the wood.

- Opening and closing the windows should be relatively easy, although some force may be required if they have not been operated for a while or if paint was applied recently. To ensure that paint is not holding the sash shut, use a sharp knife to score the juncture at the operable sash and the interior sash stop. Sometimes, a hard bump with the hand along the stiles can break a paint bead after scoring—raising and lowering the sashes should rub off any paint causing them to stick.

Hardware

With repeated use, oil-rubbed bronze finishes wear down over time. Hardware with oil-rubbed bronze finishes is not recommended for use in high-traffic areas or external locations, as the coating will break down prematurely, resulting in a patchy appearance.

Click here to download Maintenance Information

WARRANTY

With proper care and maintenance, this window will last 100 years. Please read the owner’s manual for the warranty details.

- Material and Workmanship Warranty: 5 years

- Weatherstripping and Screens: 1 year from date of delivery

- Glass Condensation: No coverage

- Glass Stress Crack Breakage: 1 year from date of delivery

- Putty Glazing: 1 year per warranty documentation

- Hardware: Hull’s discretion Weight and Pulley System: No coverage

- Paint Finish: 1 year from date of delivery if factory finished by Hull

- Interior Stain and Clear Coating: 1 year from date of delivery if factory finished by Hull

- Coastal Installations: No coverage; properties within 1 mile of the coast

- High-Humidity Areas: No coverage; greenhouses or indoor pools

Click here to download Warranty Information

FREQUENTLY ASKED QUESTIONS

- How do I measure for a window? Please refer to how to measure guideline for both new construction and replacement.

- How often do I need to check my windows to ensure their quality? Hull recommends checking your windows every 6 months. Please refer to maintenance and care guidelines for a checklist of items to look for.

- Why should I pick the 100 Year Window over other windows?

Wood Quality: Choosing the right material is critical to a window’s longevity. With over thirty years of research and experimentation, Hull windows are made from the most durable wood species, including tropical hardwood sapele, white oak, and long-leaf yellow pine.

Construction Details: What makes a good window a great window is about an 1/8”. The depth and profile of the 100 Year Window is based on historic precedent, providing a richness and charm production windows lack. The 100 Year Window also has true divided-lite and solid wood stile and rails with absolutely no finger joints.

Energy Efficiency: The 100 Year Window meets U-value standards and passes ASTM infiltration tests.

Weather Stripping: V-groove bronze weatherstripping provides the best year-round solution. It allows for expansion and contraction while helping with air infiltration and making the windows easily operable.

Glass: Period-authentic single pane, putty-glazed glass avoids cracked seals and condensation unlike insulated glass. When 20% or less of a wall is glass, it is neither necessary nor cost effective to spend money on insulated glass which only has a life expectancy of about 15 years. - Will Hull really stand behind the window for 100 years? Yes. With proper care and maintenance, this window will last 100 years. Please read the owner’s manual for details on maintenance and warranty.

- Can the window be ordered with wavy glass? Yes. We offer 1/8” annealed, wavy, and vacuum insulated glass.

- My windows were delivered unfinished. How do I prove the windows were finished within 14 days of delivery? Customers are responsible for taking time and date-stamped photos that show the finished product and submitting them to [email protected] within 14 days of delivery.

- Why is my window difficult to open and close? Opening and closing the windows should be relatively easy, but force may be required if it has not been operated for a while or if paint has been applied recently. To ensure that the paint is not holding the sash shut, use a sharp knife to score the juncture at the operable sash and the interior sash stop. Sometimes, a hard bump with the hand along the stiles can break a paint bead after scoring—raising and lowering the sashes should rub off any paint causing the window to stick.

- Why is there condensation on my window? Condensation on windows often occurs naturally due to humidity within the property. Changes in interior and exterior temperatures, interior ventilation, and duct work, shading, and sun exposure all contribute to natural condensation.

- Can I order a samples window or swatches of materials? Yes. Please email us at 100yearwindow@brenthull.com to discuss.